Project Development Blog Entry

- Eshvin Kaur

- Feb 19, 2023

- 8 min read

Updated: Feb 19, 2023

Hey guys it's me Eshvin👋🏻👋🏻.

Unfortunately, this will be my last blog related to CPDD😭😭😭

I have thoroughly enjoyed blogging about my journey in CPDD🖤🖤🖤

and also in last semester's ICPD module and I am grateful that I can share it with my viewers😁😁 🙏🏻🙏🏻and share the knowledge that I gained throughout this module.

Although this is my last blog, I will be sharing with yall how my group and I planned, designed, executed, and assembled our

PROTOTYPE OF THE CHEMICAL DEVICE‼️‼️🥳🥳

DOESNT IT ALREADY SOUND EXCITING⁉️⁉️👀👀

I PRESENT TO YOU MY TEAMMM THE 4️⃣VENGERS‼️‼️

VALERIE👩🏼💻

THE CEO/ TEAM LEADER

ASRAF👮🏼♂️

THE CHIEF OPERATING OFFICER (COO)

ESHVIN👩🏼🔬(myself)

THE CHIEF SAFETY OFFICER (CSO)

INSYIRAH👩🏼💼💸

THE CHIEF FINANCIAL OFFICER (CFO)

Our Team Chemical Device

The objective of this device is to prevent inhalation of toxic fumes during soldering which can cause occupational asthma or worsen existing asthmatic conditions; as well as cause eye and respiratory tract irritation.

Why did we choose to work on this?

Students and lecturers are commonly exposed to these toxic gases when soldering during their practical lessons or projects. In order to reduce the toxicity of the fumes, we decided to create a fume extractor that utilizes a fan using a negative draft to pull fumes and dust particles into a contained filtration system. This process removes hazardous particles from the air.

My team has made a prototype of a fume extractor ☢️.

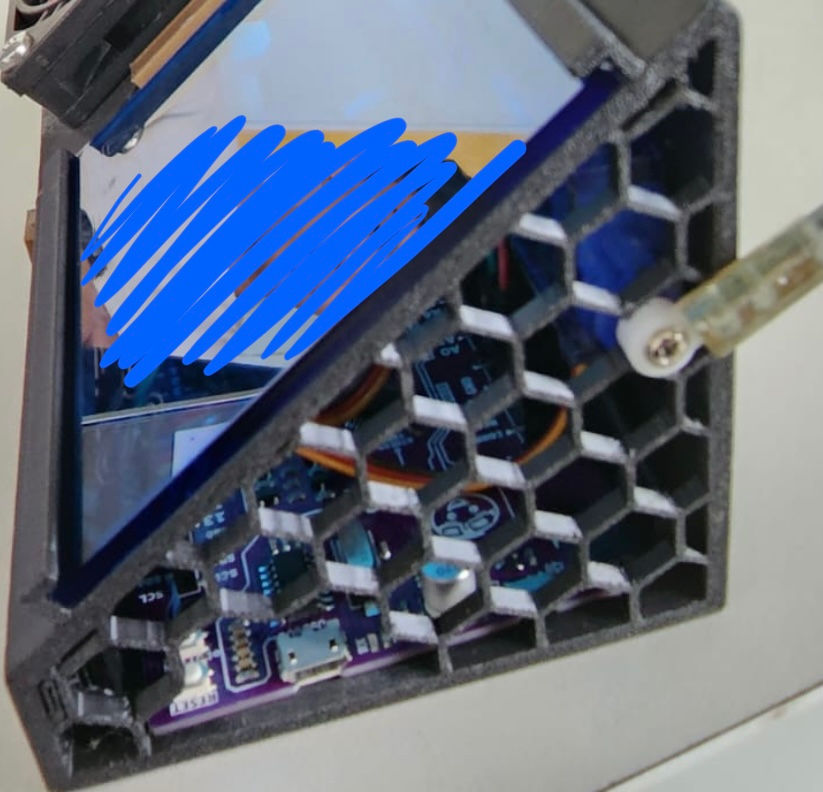

As you can see on the🔝, on the back of the device, there is a fan ☢️ that has a filter installed on top of it to filter out the soldering fumes particles 💨. It is angled 📐 in such a way as to prevent the fumes from blowing to any individual that is facing in front of the fan ✅.

At the side of it is the wirings of the servo, sensor, and Arduino board that is covered with a transparent cover of our team logo.

The purpose of the servo is an indication to let the users know that toxic fumes💨 are being detected 🚨hence the device is operating ☑️.

As you can see at the🔝, the front side of the prototype is the sensor with a "window" 🪟 at the side. The purpose of the "window" 🪟 is to absorb the soldering fumes 💨 and thus the fan ☢️ will blow it out into the atmosphere after filtering it. The flag 🚩 at the side is attached to the servo. When it senses fumes💨, the fan ☢️ will turn on and the flag will raise ⬆️. However, when there are no ❌ fumes💨, the fan ☢️ is off and the flag 🚩 is raised down ⬇️.

Using this chemical device, it will reduce the number of hazards and dangers that students and lecturers encounter while doing these tasks. As such, this device promotes workplace health and safety(WSH).

What it is. What problems will the chemical device solve?✅

Users need the fume extractor to remove the soldering fumes 💨 because of the harmful gases such as lead oxide ⚠️ that it gives out. This will ensure the safety of the students and lecturers when they do soldering during their practical lessons👷🏻. It is important to solve as it aims to reduce the number of hazards and dangers⚠️ that workers encounter while doing these tasks.

Hand sketch ✍🏼 of the chemical device

Skit🎥

my group decided to do a mini advertisement for our device.

PLS DONT JUDGE US IT WAAS HARD TO ACT WITH A STRAIGHT FACE 😮💨😭😭

Allocation and Execution🛠

The Finalized BOM (BILL OF MATERIALS)💸💸

The picture on the 👉 shows the items that we purchased.

The table below shows what my group purchased to make the fume extractor

The Finalized Gantt chart (planned and actual) and

the tasks allocation for each team member.

Design👩🏼🎨 and Build👷🏼♀️Process

In this section, I will provide documentation📄 of the design👩🏼🎨 and build 👷🏻process.

Part 1. Design of prototype and Coding (Exhaust Fan & Servo) (done by Asraf) ⬇️⬇️

Part 2. Fabrication and Coding (combine both codes) (done by Valerie)⬇️⬇️ https://valeriegoh32.wixsite.com/cp5070/post/blog-6-project-development

Part 3. Buying of material, Assembly of Prototype (done by Insyirah) ⬇️⬇️

Part 4. Clean-up of fabrication 🧹 and Design of Logo ☢️ and Flag 🚩

(done by ME, Eshvin)

Design of Logo☢️

for the design of our team logo ☢️, I wanted to have something simple and not gaudy. Since we were doing something related to a "fan". Instantly I wanted that as our logo so I used "looks" which is a website that designs logo. YES I KNOW ITS KIND OF SIMPLE BUT THAT WAS THE PLAN😩

However, when we printed it 🖨, we added our names on top of it as you can see on the right 👉.

Design of Flag🚩

for the design of the flag 🚩, the purpose of it is when there are fumes 💨 detected, the flag on the servo will rise up ⬆️ and if it does not it will go down ⬇️. Thus I intended to put like a scary image or logo ☠️ on the flag 🚩 as when it is raised up ⬆️, the user can see the "scary" image ☠️ and he/she would know that the extractor has sensed the fumes 💨 and it is time for him/her to be cautious while working with the extractor👷🏼♂️. This is the design that I came out with.

This was the result

As you can see on the right 👉, the flag is up ⬆️ and although the skull head ☠️ cant be seen due to the tape that is on it, it means the fumes💨 are being censored🚨 by the extractor.

Cleaning up the fabrication🧹

Although the correct dimensions and parts were printed 🖨, there were specific changes to be made 🤔.

As you can see on the left 👈, there is a gap on the perforated side of the design. Initially, that side was just covered with holes, however, we realises that it was kind of difficult 🧐 to plug the USB into the port of the Arduino board.

So we cut some of the holes and use sandpaper to smooth the sides and the base.

As you can see on the right 👉, there is a weird gap in the circle. It is because when the wire of the fan ☢️ is inside the circle, the wire will then rub off the wall of the circle which can cause the wire to gain friction and it may lead to something hazardous ⚠️. Thus to prevent it, I melted the bottom right side of the circle to allow the wire to rest on it and not move around.

As you can see on the left 👈, the sensor is being fitted between the two parts of the design. However, after printing 🖨 the parts, we realized that the sensor could not fit the gap between the 2 parts as the gap was too small. So we sand off the sides of the two parts till the sensor can fit in it as you can see on the left 👈.

As you can see on the right 👉, the perforated holes absorb the soldering fumes💨. However, after it was printed 🖨, there were so many of remaining supports on the side of the holes and it was not smooth either. The holes look really messy if you get what I mean 😵💫. That was not aesthetically pleasing, also if there were a lot of obstructions, the fan ☢️ would not be able to absorb the fumes 💨 easily thus the extractor would not perform to its potential. After using tweezers to take out the remaining supports and using sandpaper to smooth the sides of the holes this is the result.

As you can see on the left 👈, there are too many wires in a very compact area. Although it is very hazardous⚠️, we could not think 🤔 of any way to reduce the number of wires to use except for opting for shorter wires. However, we thought of clipping the wires up and cable-tie some of them to minimize the hazardous chances⚠️. The clip-ons were printed 🖨 by Asraf as you can see on the left 👈.

Hero Shot 📹 of Us Cleaning Up The Device 🧹

Fusion Design 💻 of the Device

The video below shows the design of the device that came about in fusion

(front side)

(back side)

A video 📹 of the device in the works

DESIGN PROCESS OF THE DEVICE😮💨😃

THE FINAL PROTOTYPE DESIGN😮💨😃

Problems😨 and Solutions😃 In this section, I will describe the problems encountered in the design and build process and how the team solved them💪🏻.

PROBLEM 1️⃣ | SOLUTION |

The hole for MQ2 Smoke LPG CO Sensor Module was too tight. | We have to keep sanding the 3D frame for the MQ2 Smoke LPG CO Sensor Module slot till it is able to fit it nicely. We purposely make it smaller than the MQ2 Smoke LPG CO Sensor Module size because we were scared that if it is too big we need to re-print the whole thing but if it is too small or too tight we are able to sand it off. The only trade-off is that it will take time to do so. |

PROBLEM 2️⃣ | SOLUTION |

The side with the hexagonal grid was too small for the wire to fit through | We trim off part of the hexagonal shape and sand it till smooth, so that is hard to be noticeable from far. |

PROBLEM 3️⃣ | SOLUTION |

Exhaust fan placement – Originally, we wanted to put it inside | The reason for putting the exhaust fan inside of the frame so that it won’t have anything protruding upwards because it will look ugly. But when we try to fit it inside, we didn’t take into consideration the inner height. So, we have no choice to place the fan outside but it turns out nice because the whole print was black and our exhaust fan was black and it create this nice illusion that forms a single piece. |

PROBLEM 4️⃣ | SOLUTION |

Servo – We assumed that our exhaust fan was a mechanism | We thought that our exhaust fan was actually a mechanism because we did some research online and ask some seniors but after clarifying with Mr. Ting apparently it is not. So, we have to figure out a way to install a servo into the prototype but we didn’t want to change anything to the design. The easiest solution that came to our mind was using a servo as a signal to indicate that the fan is on or off. So, we attach a flag to the servo and place it at the side. And it works. |

Project Design Files as downloadable files

Learning Reflection ✍🏼 on the overall Project Development

It has indeed come to an end 😩😩. Compared to the prototype that my group did for ICPD to CPDD, this was far way tedious 😮💨😪. First for most, a shoutout to my teammates Asraf👨🏼💻 and Valerie👩🏼💻 that worked tirelessly for this device especially the coding as that was not an easy job to be done 🙏🏻🙏🏻🙏🏻. Unfortunately, I do not possess good coding skills 👎🏻, so I feel bad 🥺 that I could not help them because it was not an easy job 😰.

Overall, I am confident that the product works the way we want it to😎. Although this is just a prototype and I am pretty sure that there isn't a device like the one we created❌, I hope the readers that are reading this get inspired😇 and recreate this device to a better-improved version 🦾 as this device is honestly really helpful to people that perform soldering as soldering itself does possess some health hazards ⚠️ thus we came out with this device to help absorb the fumes 💨 and filter it out.

The making of the device has indeed gone successful 🤙🏻🤙🏻. I have thoroughly enjoyed my ICPD and CPDD with Asraf, Valerie, and Insyirah🖤. We definitely have made good memorable memories with one another😃. It is sad indeed that we are not going to be in the same group for FYP however I thought that was actually a good thing for me personally. Personally, I feel that I have always been reliant on Asraf and Valerie when comes to the main part of the job I never realized that in that way I am not gaining any knowledge or I will never learn anything new just because I am not good at that particular thing. Thus I have thought of learning basic coding or taking up a coding course for the holidays. Also learning how to fully improvise in fusion with the help of youtube. In that way, I will be able to help my FYP group and also be fully participative in it, knowing that I cannot rely on others and that I have to take up these responsibilities will only make me better as a person and also skillfully. Well, it is what it is. I have set my goal for FYP and I will start to work towards it 💪🏻. Enough about my thoughts 😂😂 and back to the device.

Throughout this CPDD journey, I definitely have learned how to laser cut✅ which will come useful during FYP or in the future. After much struggle, I have also managed to understand Hypothesis Testing ✅which will also come in handy for my FYP. Going through the experience of coming up with a need statement to actually make this device, makes me feel better prepared to take up a project as I know what I need to find out or do✅. The only thing that may hinder ☠️ my pathway to a good journey 👍🏻 in FYP is maybe my hands-on skills which I intend to build upon💪🏻 as previously mentioned.

Last but not least, I really really appreciate the fact that

I got the chance to work with Valerie, Asraf, and Insyirah 🖤🖤🖤

just the hyper 4vengers peacing out😎

Comments