LASER CUTTING BLOG ENTRY ⚙️✂️

- Eshvin Kaur

- Nov 7, 2022

- 3 min read

HEY EVERYONE!!! I am back with another blog for (Chemical Product Design & Development) CPDD, an upgraded version of ICPD 😆🥳. Well, I hope that yall enjoy my previous blogs because I am back to continue this journey🤩🤩🤩 For this blog, I will be talking about my laser cutting experience and I hope yall will gain some knowledge while reading it.

SO LET'S BEGIN ⬇️⬇️⬇️

4 important hazards‼️ and respective safety control measures👷🏼♀️ on the operation of laser-cutting machines

Hazards 📛 | Safety control measures ⛑ | Pictures to support the explanation |

Physical Hazard ⚠️ (Exposure to the laser beam for long can cause severe eye damage or skin burns.) | DO NOT stare into the beam while cutting, glancing it once a while is fine. |  |

Health Hazard 🌫 (Inhaling the toxic smell) | DO NOT lift the lid immediately, let the extractor remove the toxic smell & particles first. |  |

Physical Hazard ⚠️ (Sharp edges could result in lacerations, and puncture wounds) | Wear working gloves🧤 and covered shoes 🥾. |  |

Fire Hazard🔥 (Remains of engraving and cutting equipment can cause fire hazards if left unattended.) | Always clean 🪠 the laser machine site once being used to prevent the accumulation of any small pieces. |  |

Materials that can be cut/engraved using a laser cutting machine in FabLab👍🏻

Material | Photo of material |

Paper/ White Card |  |

Cardboard |  |

Balsa wood |  |

Plywood |  |

Acrylic |  |

Below are the materials that can’t be cut/engraved using a laser cutting machine in Fablab👎🏻

Material | Photo of material |

PVC |  |

Metal |  |

Foam |  |

Rubber |  |

Below are the steps for the operation of the Universal laser cutter machine in FabLab 🔖

a) Starting the compressor, turning on the laser cutting machine, and fume

extractor.

T1442📍

Before you start, switch🔌 on the power for

the laser cutter, Air Assist, and Extractor

Light Switch

MAKERSPACE📍

Before you start switch🔌 on the power for

1) the laser cutter, Air Assist and Extractor

2) Switches for the fume extractor

b) Importing a . DXF file to CorelDraw and modifying the lines/fill for cutting

and engraving.

1) Importing from Fusion to Corel Draw Select File > Import > Select your.DXF file and press import > press ok |  |

2) Once imported, you will need to make a decision on which one to vector cut, engrave, or vector engrave by double clicking the black box. |  |

3) Click on Colour and under the colour model change to RGB with Red🔴 being 0, Green🟢 being 255, and Blue🔵 being 0. Once done Click OK ✅. |  |

4) Under Width, change the Style to the Hairline. Once done Click OK ✅. |  |

5) Click on the colour and under the colour model change to RGB with Red🔴 being 255, Green🟢 being 0, and Blue🔵 being 0. Once done click Ok ✅. |   |

6) Under width change the Style to the Hairline. Once done click ok ✅. |  |

c. Sending the CorelDraw drawing to laser cutter software and setting the

laser cutter power, speed, and PPI in the software.

Steps and description | Photos to support the description |

1) Click on File > Print 🖨 |  |

2) Click on the Cogwheel ⚙️ for settings🛠 |  |

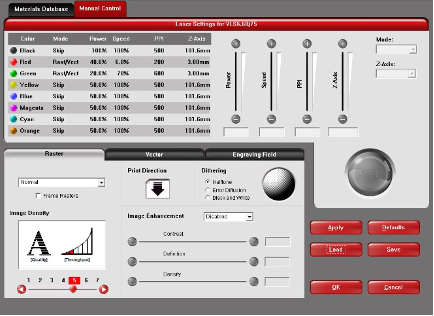

Universal’s Material setting will appear.

3) Click on LOAD for more material settings |  |

4) Select the presets that match your material type and thickness and select OPEN |  |

5) Once done Click OK ✅ and Print 🖨 |  |

d. Starting the job on the laser cutter machine.

Steps and description | Photos to support the description |

1) Simply click🖱 on the UCP (Universal Control Panel) icon |  |

2) Place the material on the top left of the machine. |  |

3) Click on the Red 🔴 power button |  |

4) Click on the Focus 🧐 Tool, and a crosshair will appear. (We will now check if our file is within the safe👌🏻 cutting area, we do not want to have our object cutting over the voids on the Plywood.) |   |

5) Click on the moving tool to move the object to the empty space of the material. Then Click on "The pointer" |  |

6) If all is good ✔️, 1) Shut the lid gently 2) Press the PLAY ▶️ button on UCP |  |

7) It is a good practice to Monitor the cut by glancing 🤨 at it. PLEASE DO NOT STARE AT THE BEAM❗️ |  |

8) Once done, DO NOT LIFT the lid immediately, let the extractor remove the toxic smell & particles first😶🌫️. For your own safety 😷, wait for around 1 Minute before lifting up the lid! |  |

9) Once extraction is done. Gently lift up the lid 😶 DO NOT ATTEMPT TO REMOVE MATERIAL YET! 😯

(We need to test to see if the material did get cut through. Tap on the cut material to see if it is free from its main material) |  |

10) Once done, 1) Remove any unwanted materials and dispose of them🗑 2) DEACTIVATE the Laser cutter by pressing the red 🔴 switch button on the computer. 3) Switch off the necessary switches 4) You need not ❌ Shut down the PC |  |

e.DOs and DONTs when there’s flame/fire on the material being cut.

DOS ✅

In case of any unmanageable 😵 fire, hit the emergency button to cut power to the laser cutter. |  |

If the fire is negligible, try putting it out by blowing it off 😮💨 |  |

If the fire is unable to blow off, a. remove material from the laser cutter b. place it on the floor and step on it to put out the fire |  |

If the fire is uncontrollable, go to the closest fire extinguisher 🧯and put it out. | T1442📍  Makerspace📍  |

DONTs ❌

DO NOT throw water💧 on the material that is in the laser cutting machine as there will cause an electric shock to the user. |  |

DO NOT run away 🏃🏼♀️ and leave others behind as by opening the hot door 🔥🚪, has the potential to invite a growing blaze inside the room. |  |

DO NOT hide under a table or in a cupboard. Not only will this limit your ability to quickly move and run if you need to, but it will also make it difficult for the fire services to find you once they get there. Hiding away like this will not protect you from a rapidly spreading fire, and will certainly not save you from the smoke and heat. |  |

Learning Reflection 📝

I had never done laser cutting before, so this was my first experience1️. To use the laser cutting machine, we were told to create an SOP using a guide provided to us. When I first looked at it, I thought it was very complicated🤯. Then I watched the video that showed how to use the laser cutting machine. To be honest, it was too much for me to take in🥱. I thought I was prepared after preparing the SOP and watching the video💪🏻. But, in reality, the package and the laser cutting are two entirely different things👀. The day came for me to take the test. I was nervous and scared because I was afraid that if I forgot anything, the test would be ruined😰. When it was my turn, I was able to import the file but got stuck at the part where I had to change the colors. I kept clicking the black box to go to the color settings, but nothing happened, and I just stared at the screen because I didn't know what was wrong😵💫. I then paused the test and resumed it once everyone had finished. I didn't realize I had to double-click the box, so when my test came, I managed to do it and the competency test went smoothly, despite the fact that I was doubting myself the entire time because I didn't know whether I was on the right track or not, and the teacher in charge kept telling me, "I will tell you if there is anything I need to do." The only reason I acted that way was that I lacked confidence and was overly nervous😓. Overall, I believe I have learned the fundamentals of laser cutting and am confident that I will be able to use this skill in my capstone project or while working😃. However, I still want to learn more about laser cutting because there are more complicated things that I can laser cut that may require additional skills or tips🤓. One thing i learned from the practical session is that being nervous is something I should try to avoid because it will lower my self-esteem🤕.

THAT IS IT FOR MY BLOG!!! I HOPE YALL ENJOYED READING IT AND HOPEFULLY BE INSPIRED TO TRY LASER CUTTING ELSE WELL! I WILL SEE YALL SOON AGAIN WITH ANOTHER BLOG! BYE!!!!!!!!👋🏻👋🏻😺😎

Comments